Importance of Load Banks in Electrical Power Systems

Load banks Testing in Electrical Power Systems

KWK-Resistors manufactures Resistive Loadbanks that can be used to test Generators, Uninterrupted Power Systems (UPS), Electrical Distribution Panels and Systems, Data centre power systems and more. KWK the largest portfolio of load banks globally with options to meet any power test requirement. Contact us today to get a Custom Quote.

Stand-by electrical power sources such as UPS (Uninterruptible Power Supplies) and diesel generators are not put to use continuously. They take over only during disruption in the main power supply, and hence may remain continuously unused for a long period of time. They may be designed for a particular power rating, but it is important to guarantee their functioning in real life situations which might involve different types of power supply disturbances such as – Transients, Interruptions, Sag / Under-voltage, Swell / Over-voltage, Waveform distortion, Voltage fluctuation or Frequency variations.

Load bank testing is a way of validating the correct operational performance and battery autonomy of the UPS system. It tests the UPS and generator under various load conditions. It helps to ensure that the power system is 100% reliable before it goes live for the first time. Also plays an important role in testing power systems for faults while performing system maintenance.

The world is entering the digital world, where 24 X 7 working of machines is a must. Fluctuation in power can hamper / corrupt the data acquired by various enterprises stored in large data centres. Load bank testing plays an important role in ensuring the reliability of these power systems.

What is Load testing, how does it work?

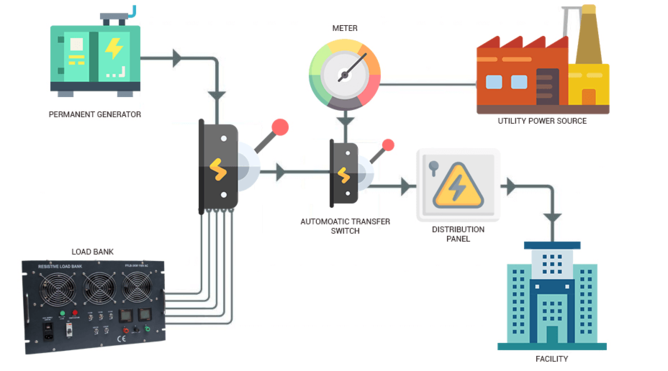

A load bank is an independent, incremental load device that can accurately mimic the operational or real load which a power source is meant to support.

The load bank typically consists of heavy-duty resistors that act as an electrical load to the power source. It dissipates the resulting electrical energy as heat, using resistive elements. The resultant heat is taken out using blowers installed within the load bank.

After conducting the load bank test, measurements are taken during discharge where the battery and system performances are noted. A load bank test identifies problems with the generator and UPS, prompting for immediate actions to be taken to improve their efficiency.

Load banks may be permanently installed at the site and always connected to a power source or portable versions can be used for testing when required.

Importance of Load Bank in Power Supply Systems

The idea behind load bank testing is to test the power source and its components to ensure maximum efficiency. UPS and power supply systems need periodic testing to ensure that they will work when actual need arises.

- Manufacturing and installation testing of Power Systems – It allows testing of all components of the system, to ensure all work together as designed and intended and can help identify any potential weaknesses in controlled conditions. Product specifications and delivery contracts may explicitly cover these testing aspects, making load bank testing a mandatory compliance step.

- Regular preventive maintenance – Not performing regular scheduled preventive maintenance and running of low load can result in high operating costs, easy wear & tear and increased emissions. A load test helps to verify that the generator system will produce and maintain full load without overheating and shutting down. This allows proactive maintenance as weaknesses are identified during controlled conditions, without risking a utility outage when a weakness can cause the system to fail.

- Elimination of wet stacking – A problematic condition called Wet Stacking commonly affects diesel engines in which unburned fuel passes on into the exhaust system. Diesel standby generators that run rarely and or only on light load tend to accumulate these fuel deposits in parts of the engine over periods of time. This makes them function with reduced output capacity when actually needed. For efficient combustion, a diesel engine should be run at least 60 percent of its rated power output. Load bank testing will help in removal of deposits from the pistons, removing engine castings and exhausts as well as noting potential weaknesses.

- Regulatory compliance – Load bank testing is a mandatory requirement for some backup power generation applications. International bodies such as The National Fire Protection Agency (NFPA) and the National Electric Code (NEC) have both drafted rules which pertain directly to the load bank testing of emergency generators.

Why load banks over building load for testing ?

Usage of Load banks is preferred when compared to the alternative method of using Building Load for testing. While using building load, electrical power from the building’s power source is transferred to the backup generator for a short period of time. However, in this method there may be interruptions when transferring the load sourced from building load, from the utility to generator. In mission critical applications such as defence or healthcare, this is not reliable. Another disadvantage with using building load is that it cannot be applied in precise, well defined steps, so that the performance can be monitored and recorded. Depending on the time of day, building load could rarely get over the required 30% load, whereas full load testing would require around 75% load. It is also ineffective in the proper discharge of UPS batteries. Load bank testing is the real reliability test of the stand-by power device as it simulates a power outage condition.

Most load banks are manufactured with incremental switching that allows the generators to be ramped-up so that block loading doesn’t damage the engine.

Load bank testing can ascertain the following conditions of a standby power source /supply such as generators and UPS:

- Can the stand-by power device provide the required power?

- Can the alternator provide the required voltage stability for the system?

- How are the control systems functioning under different load conditions?

- What is the stable operating frequency?

- What is the oil and fuel pressure?

- How is the overall performance of the load bank system?

- For Load optimization in prime power applications

What are the different types of Load Banks?

The different types of load banks can be categorised based on the following factors:

- Based on component characteristics (Resistive, Reactive – R/L/C)

- Based on interfacing (Manual & Interfacing with digital IOs through Potential contacts)

- Based on electrical characteristics (AC or DC)

- Based on mounting, construction, portability & size, installation (Indoor, Outdoor)

Resistive Load Banks

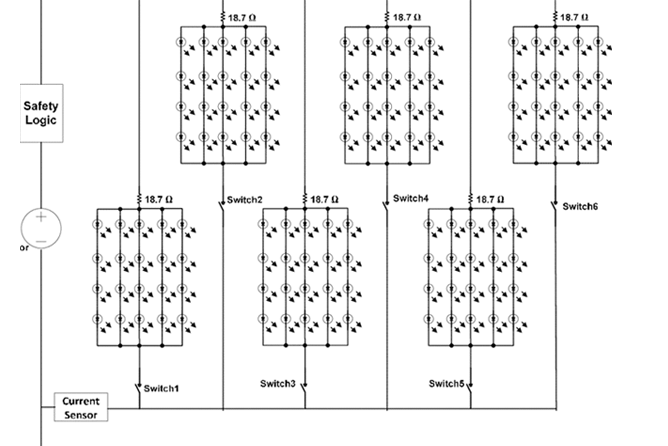

Schematic of Resistive Load Bank

Resistive load banks are the most common type. They have an important characteristic which provides equivalent loading of both the generator and prime mover. So, for each KW (or HP) of load applied by the load bank to the generator, an equal amount of load is applied to the prime mover by the generator. The resistive load bank allows you to test a prime mover and a generator at 100% capacity.

Resistors are of unity power factor. So resistive load banks have no initial switch-on surge. Current rises immediately to a steady state.

The type of resistive element used could be Wire wound type, SS Punched Grid and Wire formed Grid. The load bank could be a permanent installation in the periphery of the power system. Or it could be a portable device, acquired only during installation or maintenance times.

Generator load banks are available for both AC and DC systems depending on the requirement. DC systems are used to test batteries while an AC load bank is used to test the entire UPS system.

Generators may be connected to full load using the Load banks, for a time period ranging from pulsed duty to a continuous operation. This process is generally repeated at least once a month, during regular preventive maintenance cycles. The equipment must always be tested with an appropriately sized load bank, never applying a load higher than the generator-rated capacity.

Load banks are made up of heating elements and fans which are responsible for cooling the system. Therefore, allowances should be made to allow heat dissipation and attenuation of noise during the testing process.

Reactive Load Banks

Unlike the case of resistive loads, the power factor in reactive loads is either leading or lagging. Such as in the case of capacitive and inductive loads:

Capacitive loads – Have leading power factor, where current leads the voltage. A capacitive load is added to a capacitive load bank in order to have a leading power factor. Capacitive loads such as Synchronous condensers, capacitor banks are examples. Capacitive load bank testing is commonly employed in UPS OEMS and Crest Factor Loads.

Inductive loads – Have lagging power factor, where current lags behind the voltage. An inductive load is added to an inductive load bank in order to reduce the PF to less than unity. Inductive loads such as induction motors, coils, lamps are examples. The most common ratio has the inductive load at 75% of the resistive load. Inductive load bank testing is commonly employed in OEM Factory Testing and Military applications.

Both inductive and capacitive load banks are normally used in conjunction with a resistive unit to provide a lagging/leading power factor load test. Reactive load banks are rated in kilovolt-amperes reactive (kVAr). Reactive loads simulate real-world operating conditions. They are commonly employed in applications with non-linear loads, especially in industries where a UPS is used. Reactive load banks support the capability to test the generator set fully at 100% kVA rating.

Resistive / Inductive (R/L) – for testing at lagging pf (usually 0.8)

Resistive / Capacitive (R/C) – for testing at leading pf (usually 0.8)

Resistive / Inductive / Capacitive (R/L/C) – for testing leading, lagging and unity conditions

What are the top Industry Applications of Load banks?

| Industry Sector | Load Bank Application |

|---|---|

| Power Sector |

|

| Industrial Automation |

|

| Data Centers |

|

| Healthcare |

|

| Telecommunication |

|

| Defence and Aerospace |

|

Resistive Load Banks from KWK Resistors

KWK Resistors is India’s only ISO 9001 certified Power Resistor Manufacturer to provide CE certified products. We are one of the top resistive load bank manufacturers in the country. KWK Resistors India is in the business of design and manufacturing of a wide variety of resistors.

KWK Resistors has years of experience with design and manufacture of resistive components used both inside various equipment as well as the resistive load banks used to test power supplies and batteries of these equipment. We support OEMs, design houses and contract manufacturers end to end – from Design to Production.

KWK has the following products in the Load banks portfolio:

- Manually operated resistive load banks

- Remotely operated load banks with potential contacts control for controlling relay/contactors through PLC or any I/O devices.

RESISTIVE LOAD BANKS – ALPHA SERIES – 19” RACK MOUNTABLE

Alpha Series Resistive Loadbanks

The ALPHA series of Load Banks fit into a standard 6U 19″ Server Rack system or can be also placed as a table-top test equipment device. Powers up to 5kW are available with these series and combinations of these units can provide for higher Power testing requirements where required. Power supply shut-off due to over current and over temperature ensures safe operations during testing and commissioning.

Features:

- Resistive test loads suitable for 19” rack mounting or Table top use

- Power range of up to 5KW available in this series

- 240VAC, 110VAC and Dual Voltage options available

- Metering available for quick reference

- Forced Air cooling for efficient operation

- Over current and Thermal protection for safe operation

- Customized solutions to cater to the specialized needs of our clients

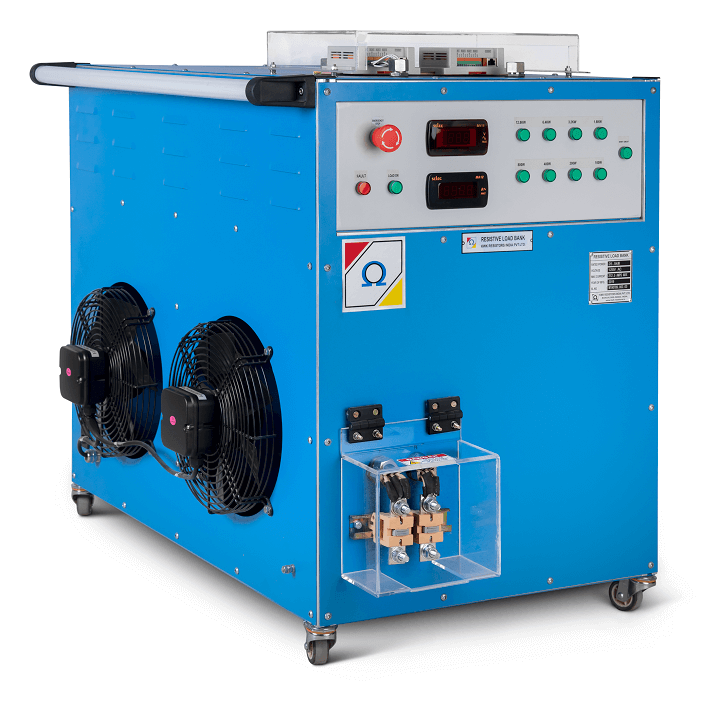

BETA SERIES – PORTABLE LOADS – STANDALONE RESISTIVE LOAD BANKS

Beta Series Resistive Loadbanks

BETA is the higher version of Alpha series. Power from 10KW to 50KW available in this series. Customized solutions are also offered to cater to the specialized needs of our clients.

BETA is a standalone structured Resistive load bank provided with castor wheels for easy movement. These series have higher safety levels like Air flow detection, Emergency Stop, Over temperature, Over Current & Short Circuit protections.

Features:

- Standalone load banks with robust design

- Power from 10KW to 50KW available in this series

- Forced air cooling with Vertical/Horizontal Air flow option for efficient operation

- DC or 50/60 Hz

- Standard Voltage 415V, 230V & 110V in AC; 24V, 48V, 72V & 110V in DC

- Dual Voltage option also available

- Load control – Manual control through switches and remote control through Potential free contacts

- Available in R,L & C combination on request

- Metering available for quick reference

- Over current, short circuit, Thermal protection, Emergency stop & Air flow detection for safe operation

- IP-20 Enclosure (Other environmental protection classes up to 32 can be provided on request)

- Customized solutions to cater to the specialized needs of our clients

| KWK ALPHA Series | KWK BETA Series |

|---|---|

| Lower Power Range – 1KW, 3KW & 5KW |

Medium Power range – 10KW, 20KW, 25KW, 35KW & 50KW |

| 19″ Rack mountable | Standalone unit with castor wheels for mobility |

| Safety Features – Over Current, Short Circuit, Over Temperature |

Safety Features – Over Current, Short Circuit, Over Temperature, Air flow sensor (to detect blower functionality) |

| Air flow direction from front to back | Air flow direction from Side to Side or from Bottom to Top |

Our clientele includes companies from varying industry sectors:

- Defence PSUs – To test supply sources, power distribution cards & units

- Electric Vehicle Manufacturers – Battery testing

- Medical Multinational OEMs – To test sources attached to medical equipment

- Power Sector Multinational OEMs and Govt PSUs – Panel testing

KWK Resistors is a global market leader in resistor solutions with satisfied customers all over the world. High power resistors, Braking resistors, Thin Film, Wire wound Resistors, Punched Grids, Metal film resistors, Resistive Load Banks – whatever the type of resistor solutions customers are looking for are available. Solutions can cater to a broad spectrum of resistance requirements – from a fraction of a watt to hundreds of kilowatts.

With world class design and manufacturing capabilities in-house, KWK excels in understanding customer’s needs and delivering customized solutions to suit them perfectly. An industry pioneer with over 40 years of experience, KWK resistors is a Joint Venture between three leading Power Resistor manufacturers – K S Instruments Pvt Ltd India, Krah Group Germany, and Widap Switzerland.

(3 votes, average: 4.67 out of 5)

(3 votes, average: 4.67 out of 5)